Next generation AI ammo inspection

Save time and resources and boost production with inline visual AI inspection

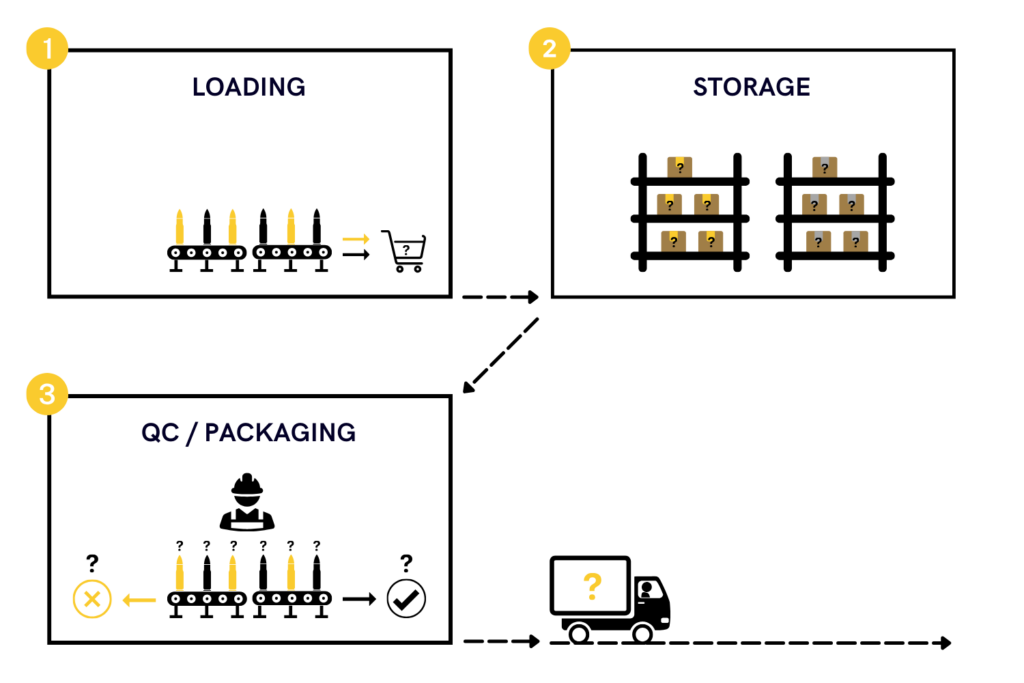

Typical ammo production finishes with a 3 step process

Ammo is inspected manually or with lasers

Manual inspection

Laser inspection

The typical process is holding you back

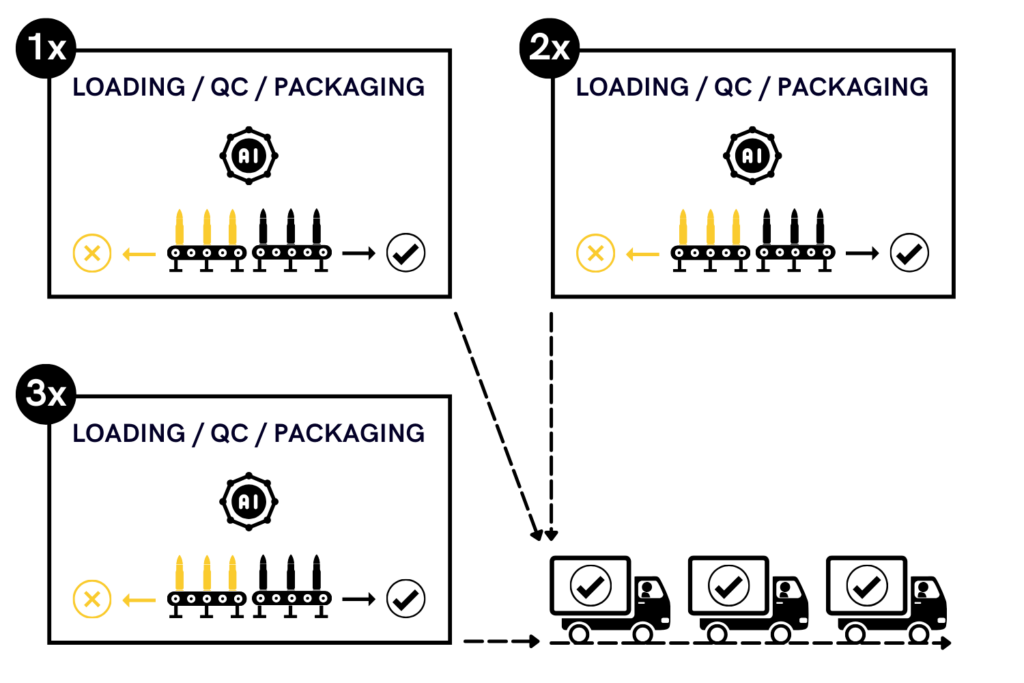

We can move you forward

We combine inline inspection and tailored AI vision so you can save space, time, and resources..

..or increase production

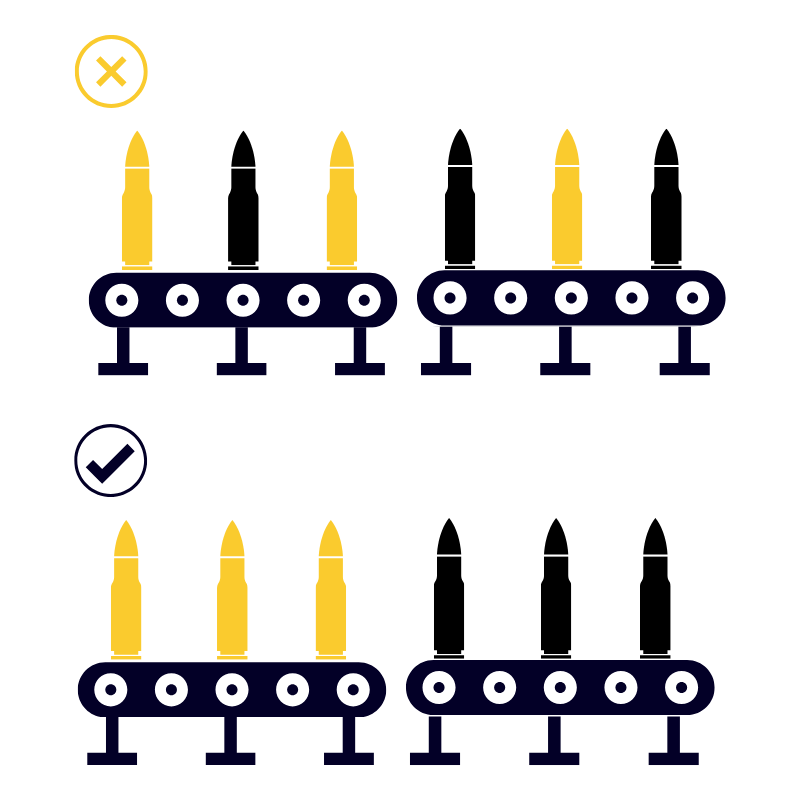

Machine vision transforms quality control

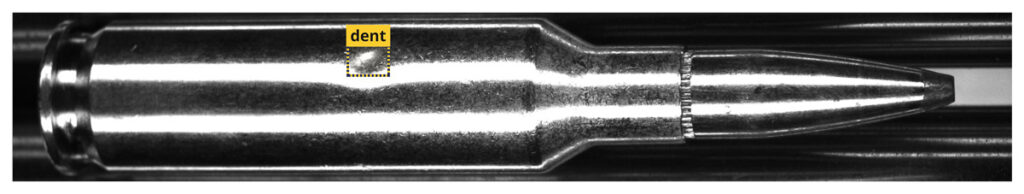

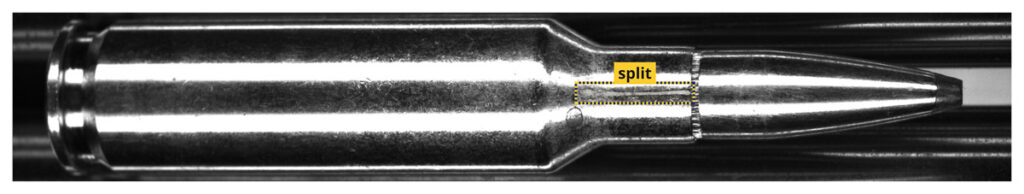

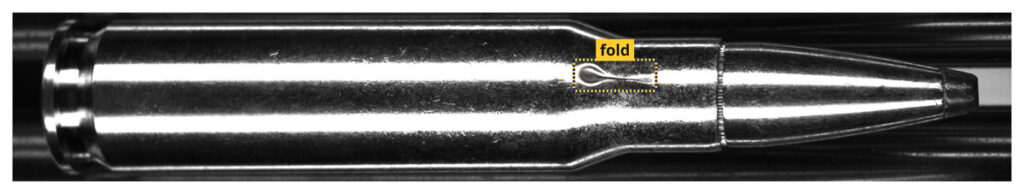

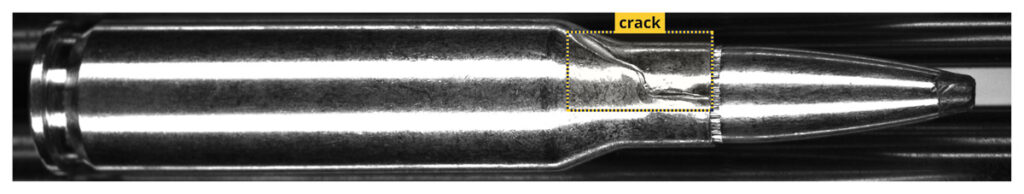

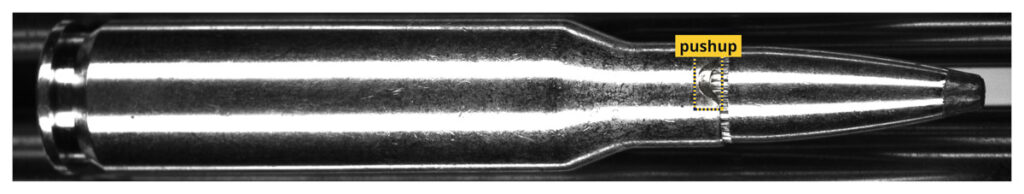

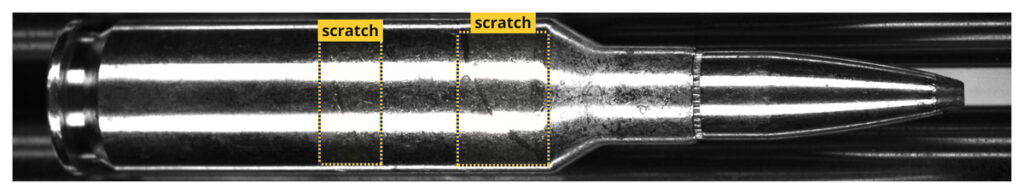

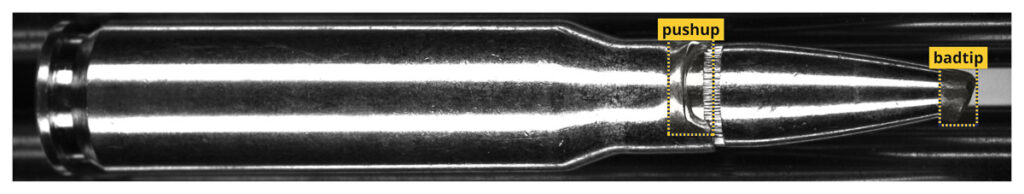

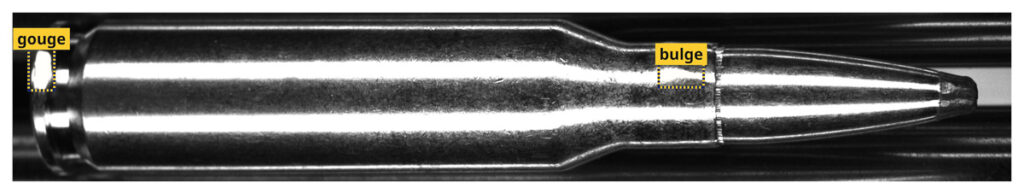

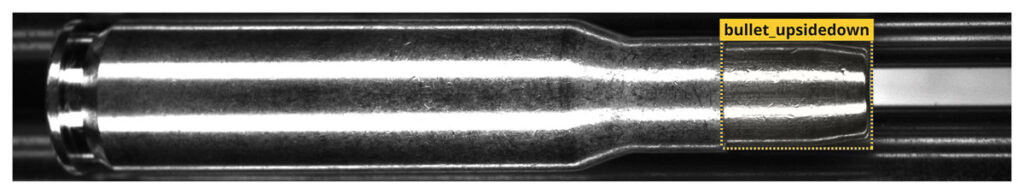

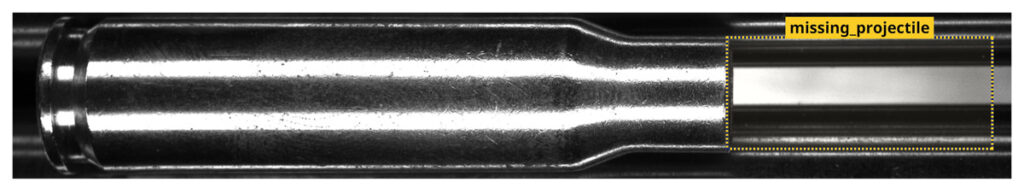

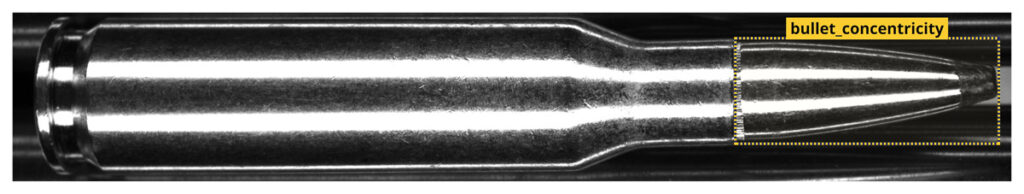

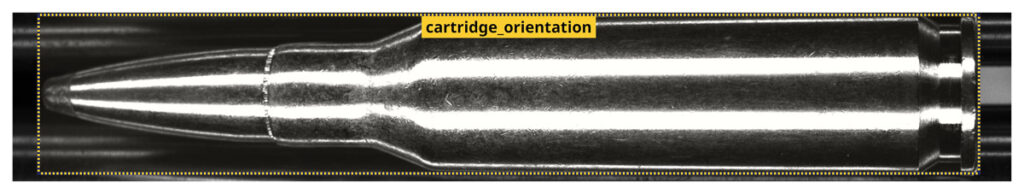

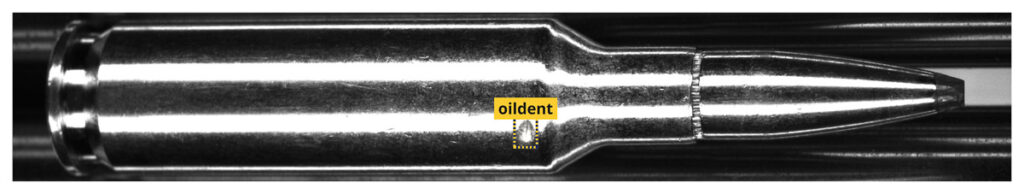

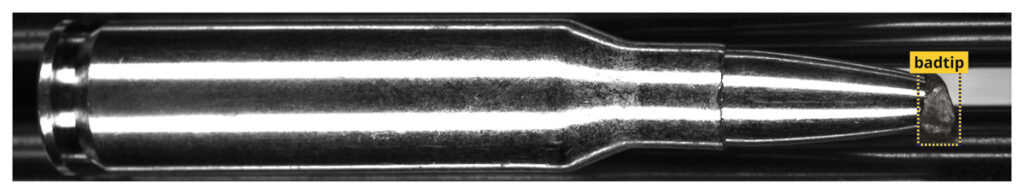

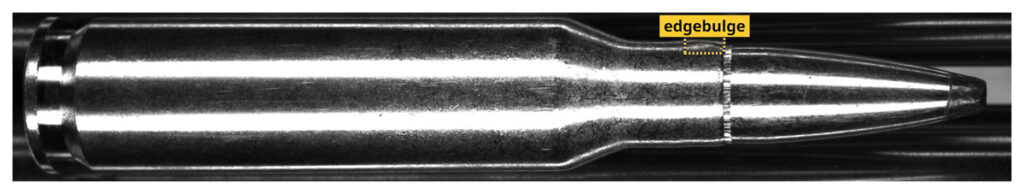

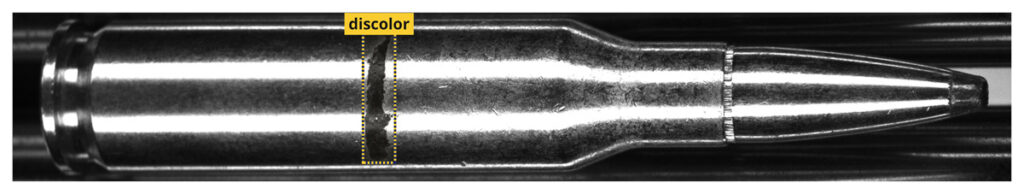

We inspect every cartridge for these defects and more

If any cartridge has any defect, we’ll find it

Advanced reporting lets you filter by..

Threshold notifications help you react faster

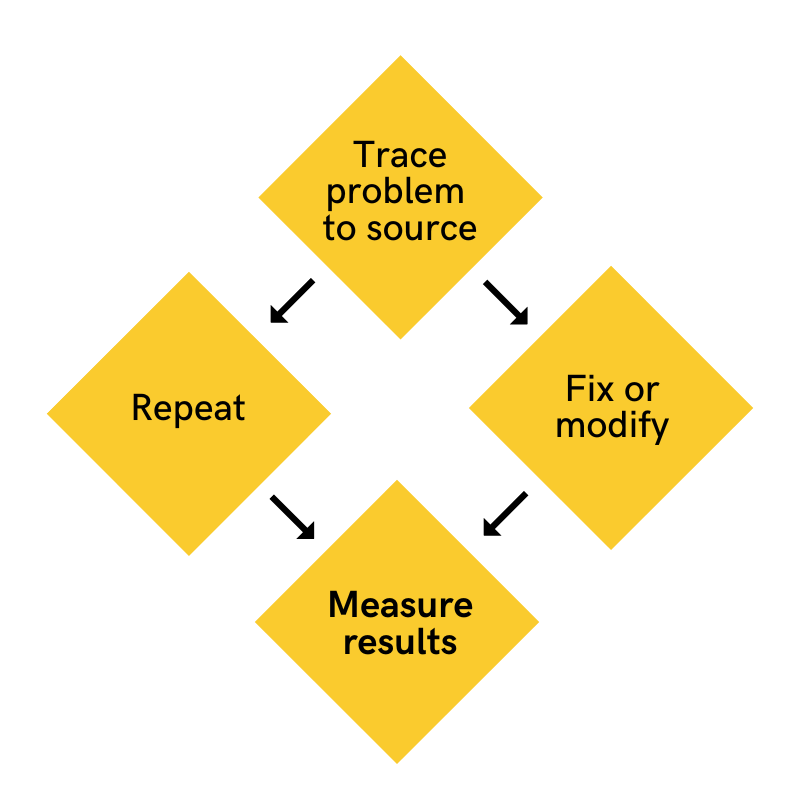

Full traceability helps you continuously improve production

So you can take a giant leap forward

Reduce

Inspection errors

Inspection costs

Wastage

Increase

Revenue

Production

Market share

Improve

Quality control

Reporting capabilities

Traceability

Ready to transform your ammo inspection?

Reach out for a free 30 minute call to discuss your production and see if we’re a good match